- Building 3 Shunheli Industrial Park,

- Lunjiao Shunde Foshan City Guandong China.

- Send Your Mail At

- [email protected]

- Working Hours

- Mon – Sat Day: 09.00 To 18.00

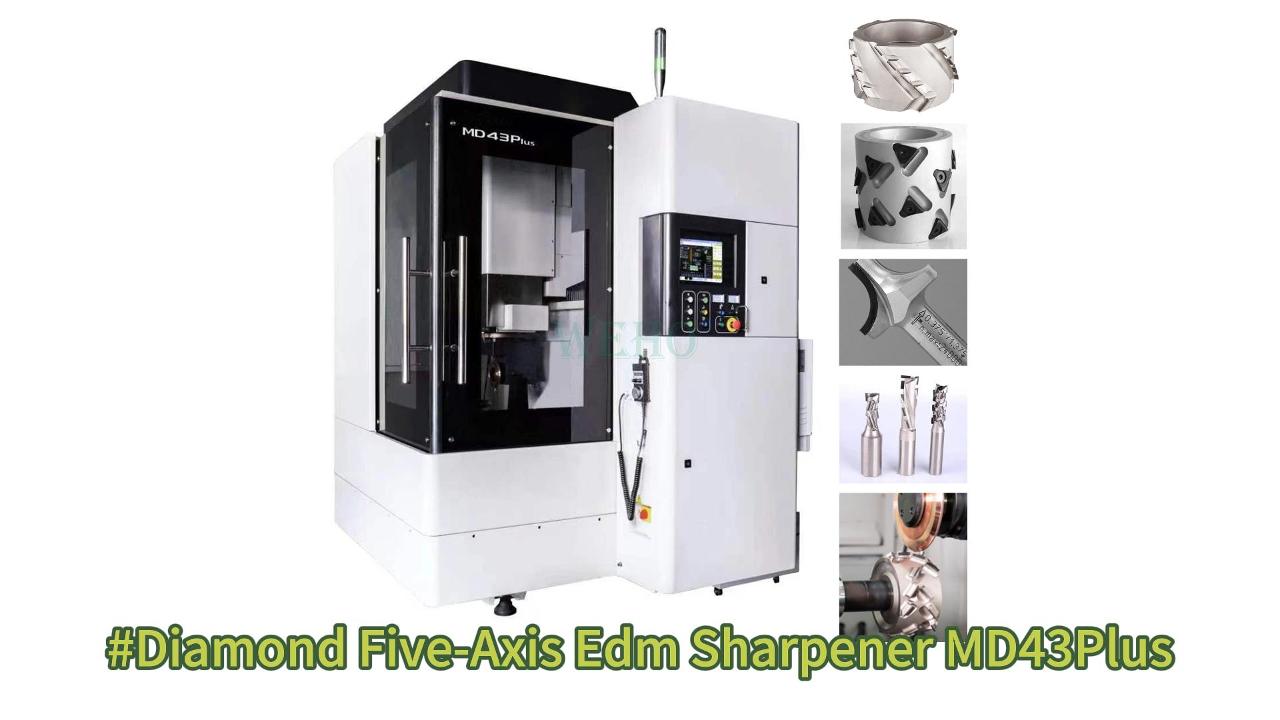

Five-axis EDM sharpener for polycrystalline diamond helical cutter and PCD materials curved cutter

X. Y and Z-axis travel: 400×260×300mm

Maximum machining diameter of spiral/disc cutter: 300mm

Minimum machining diameter of spiral cutter/shank cutter: 8mm

Maximum machining diameter of gong knife: 100mm

Minimum machining diameter of gong knife: 8mm

Maximum machining diameter of saw blade: 400mm

Minimum machining diameter of saw blade: 80mm

Maximum machinable height: 200mm

Maximum machinable helix angle: 70°

A-axis rotation angle: 0-360°

A-axis installing the tool holder jumping accuracy: <0.01mm

MD43PLUS is a discharge corrosion sharpening and regrinding machine tool for polycrystalline diamond (PCD) spiral tools and PCD superhard curved surface tools.

The machine tool can realize X, Y, Z, C and A five-axis linkage processing, automatic spiral angle detection, full-disk tool automatic processing,high efficiency, high precision and perfect automatic control, so that the processed tools fully meet the design and use requirements.

| Name |

Five-axis EDM sharpener |

|

Model |

MD43Plus |

|

X. Y and Z-axis travel |

400×260×300mm |

|

Maximum machining outer diameter of spiral/disc cutter |

300mm |

|

Minimum machining outer diameter of spiral cutter/shank cutter |

8mm |

|

Maximum machining outer diameter of gong knife |

100mm |

|

Minimum machining outer diameter of gong knife |

8mm |

|

Maximum machining outer diameter of saw blade |

400mm |

|

Minimum machining outer diameter of saw blade |

80mm |

|

Maximum machinable height |

200mm |

|

Maximum machinable helix angle |

70° |

|

A-axis rotation angle |

0-360° |

| A-axis installing the tool holder jumping accuracy |

<0.01mm |

|

Online detection of tool machining accuracy |

<0.02mm |

| Spindle speed of electrode wheel | 0~1500rpm |

|

Machine tool noise: maximum noise under working conditions |

<78db |

| Maximum processing current | 5A |

| Workbench size (length x width) | 1000×700mm |

| Number of T-slots on the workbench for clamping | 5 pieces |

|

T-groove size |

14mm |

|

Distance between T-slots |

100mm |

|

Fuel tank size |

1600*1100mm (L type maximum size) |

| Fuel tank capacity | 250L |

|

Filtering method |

Interchangeable paper core |

|

Number of filter cartridges |

2 pieces |

|

Oil pump power |

0.37Kw |

|

Working fluid |

Spark discharge fluid |

|

Electrode diameter |

Standard configuration 160mm, maximum usable up to 220mm |

|

Power grid input |

~380V 50Hz |

| Allow fluctuation range | +10% —— -5% |

| Input power | 6KW |

|

Fuse rated current |

25A |

|

Air source pressure |

0.6~0.8MPa |

|

Adjust the air source processing components to |

0.4MPa |

|

Machine tool pneumatic interface |

φ8 Tracheal quick connector |

|

Host size (width x depth x height) |

1960x2000x2460mm |

|

Machine weight |

About 3000kg, wooden case (about 220KG) |

|

Packaging box size (depth, width, height) |

2345*2240*2760mm |

|

Packing Type and number |

wooden case, 1 piece |

Product features:

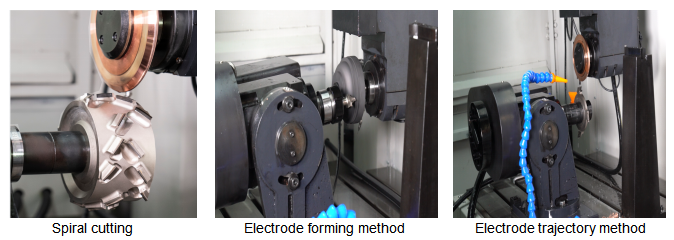

1)spiral tooth spiral line automatic detection, full disc tool automatic processing.

2)machine tools haveX,Y,Z,A,Cfive servo axes, can be multi-axis machining.

3) Aaxis high precision CNC indexing,Caxis high precision CNC rotation.

4)adopts AC servo drive

5)semi-closed loop control, μ-level machining accuracy

6)High efficiency, high finish processing

7)Mechanical accuracy remains stable for a long time

8)stepless speed regulation high precision electric spindle

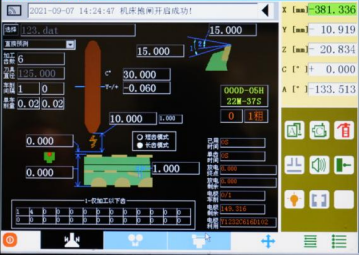

9)industrial grade15inch LCD display, display clear and intuitive.

10)equipped with a special software library for sharpening all kinds of tools, superior performance.

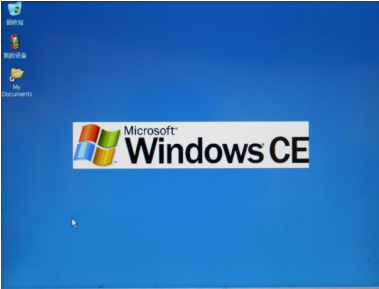

11) WindowsOperating Platform AdoptionWin7system provides operators with clear production process monitoring windows, parameter setting windows, machine tool debugging and calibration windows and other auxiliary function windows. The process monitoring window provides a digital position indication.

12)to provide customers with cost-effective superior ultra-subtlePCDdedicated discharge circuit, high-speed single-chip microcomputer control, according to the processing conditions automatically modify the discharge waveform, such as energy pulse control circuit to ensure precise control of discharge energy can effectively improve the processing efficiency and can ensurePCDtool is machined surface and cutting edge quality.

13)Through the human-computer interaction interface (UI) Receives user input and displays device status. The parameter setting adopts the fill-in-the-blank method, no code programming is required, and the program itself automatically completes the preparation of the processing program (processing code, tooth measurement code, turning code). The software itself has a parameter validity check function. The status display includes the system status (initialization/is normal./processing/alarm, etc.), coordinate display and other functions.

14)automatic processing starts to be automatically processed according to the set parameter groups that need to process the workpiece depth and rough, medium and fine processing respectively, the processing process is completed at one time, the complexity of manual operation is reduced, and good consistency can be guaranteed.

15)its realization of spiral knife edge surface processing, linear axis and rotation axis of the linkage processing. The overall machining process adopts the EDM discharge trajectory tracking method, and the linear axis control accuracy is0.001mm, the indexing axis control accuracy is0.001degrees.

16)built-in digital control unit to achieve five-axis position motion control,I /Ointerface uses complete opto-isolation. The unit has multi-axis interpolation function, zero point alignment, automatic adjustment of feed speed according to the discharge gap signal, short-circuit automatic back-off and other functions.

17)Automatic detection and adjustment function of discharge state, automatically adjust the correct discharge gap, so that the processing can maintain good results

18)uses touch screen input and Chinese menu display, which makes the operation convenient, quick, intuitive and friendly. It can not only make experienced veterans handy, but also make inexperienced novices know it at first sight. The compact and convenient manual control box has powerful functions and can complete most of the operation work. Through the soft magnetic rubber on the back, it can be easily adsorbed at any suitable position, so that the operator can operate the machine at close range and the processing preparation is easier.

19)High-precision, high-automation automatic indexing device, plus horizontal direction360degree rotation, realize automatic measurement and recording angle, combined with software control, multi-tooth tool processing is completed at one time.

20)Adopt beltRis linked with the two axes of the machine tool to realize the processing of the spiral knife.

21)machining, two-axis linkage is used to automatically turn the arc electrode. Automatic re-machining.

22)repeat positioning accuracy.

23)Realize the automatic processing of diamond spiral knife in the whole process, and the runout accuracy0.02mm.

24)realize the process of machine tool processingAaxis automatically rotates, andYshaft fit enables machining of spiral tracks.

25)Machinable spiral cutter maximum diameter300mm, can process the maximum number of teeth of the spiral knife120.

26)Minimum diameter of tool for machining shank8mm, the minimum number of teeth can be processed spiral knife1.

27)appearance is convenient to operate, maintenance and disassembly is convenient, beautiful and generous.

28)machine tool is made of high grade inoculated cast iron, and the structure of the optimized design has high static and dynamic rigidity.

29)spindle adopts a high-rigidity structure and can be used for high-precision discharge machining.

30)spindle adopts AC servo drive technology, which can realize stepless speed change forward and reverse.

31)guide rail is imported precision linear guide rail. Ensure the motion accuracy and sensitivity of the machine tool, high precision and good stability.

32)imported precision grade ball screw, pre-stretched structure. The three axes have better dynamic stiffness and resistance to thermal deformation.

33) X\Yaxis ball screw and drive servo motor direct drive, no transmission cumulative error, repeat and high positioning accuracy.

34)machine tools are in line with international standards.

35) PCmicrocomputer control,High degree of automation; stable and reliable performance.

36)light touch operation;feel good.

37)work friendly interface;display information rich;various tips are accurate.

38)automatic display alarm;function is perfect.

39)photosensitive protection and temperature automatic fire extinguishing device to ensure the safety of machine operation.

40)using Italy imported oil pump, low noise, high reliability.

Actual processing pictures:

Control system

Advanced industrial computer is adopted, with LED touch screen, legitimate version of WINDOWSCE operating system, simple interface, easy to operate, powerful memory and interface configuration, which provides a good platform for the continuous improvement in the future.

Servo and pulsed power supply

The adaptive control system adjusts the tracking system promptly according to the discharge state in the processing process, so as to make the processing process more stable. The innovative PCD dedicated and other energy pulsed power supply can ensure the accurate control of discharge energy. Combined with the intelligent discharge gap control system, the pulse utilization rate can reach the optimal state, so as to improve the quality of cutting edge on the tool surface and maintain efficient machining.

Types of machinable tools

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve, our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send spart parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact Whatsapp 0086 13378477841. After buying, technical supporting contact 0086 13326792205

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.